Learning Discriminative Illumination and Filters for BTF Classification |

| |

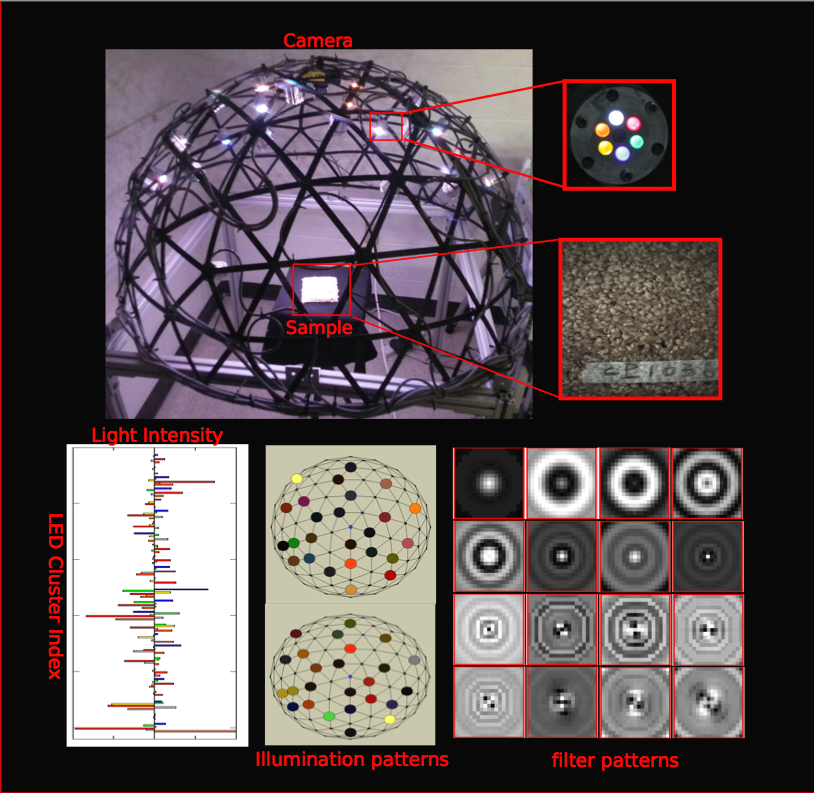

We present a computational imaging method for raw material

classification using features of Bidirectional Texture Functions

(BTF). Texture is an intrinsic feature for many materials, such as

wood, fabric, and granite. At appropriate scales, even " uniform "

materials will also exhibit texture features that can be helpful for

recognition, such as paper, metal, and ceramic. To cope with the

high-dimensionality of BTFs, in this project, we proposed to simultaneously learn

discriminative illumination patterns and texture filters, with which

we can directly measure optimal projections of BTFs for

classification. We also studied the effects of texture rotation and

scale variation for material classification. We built an LED-based

multispectral dome, with which we have acquired a BTF database of a

variety of materials and demonstrated the effectiveness of the

proposed approach for material classification.

|

Publications

Chao Liu, Gefei Yang, and Jinwei Gu. Learning Discriminative Illumination and Filters for Raw Material

Classification with Optimal Projections of Bidirectional Texture Functions. CVPR 2013.

Chao Liu, Gefei Yang, and Jinwei Gu.Supplementary

Document (with proof and other experimental details).

|

Images

|

|

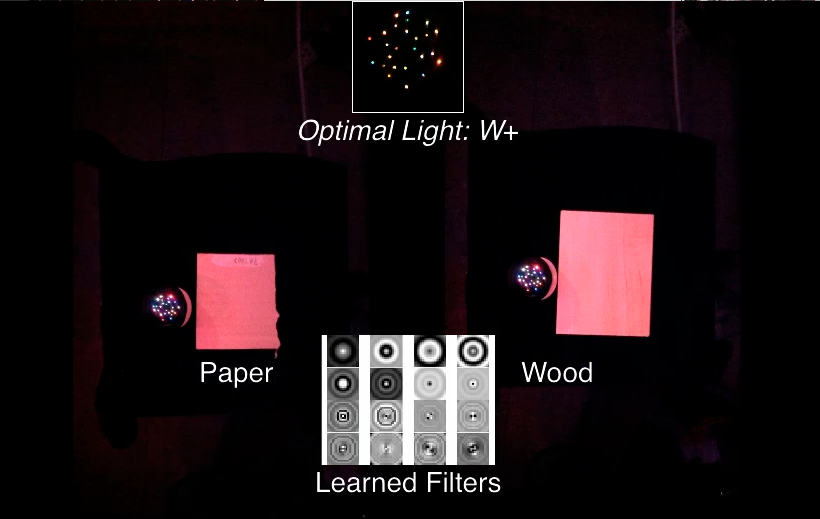

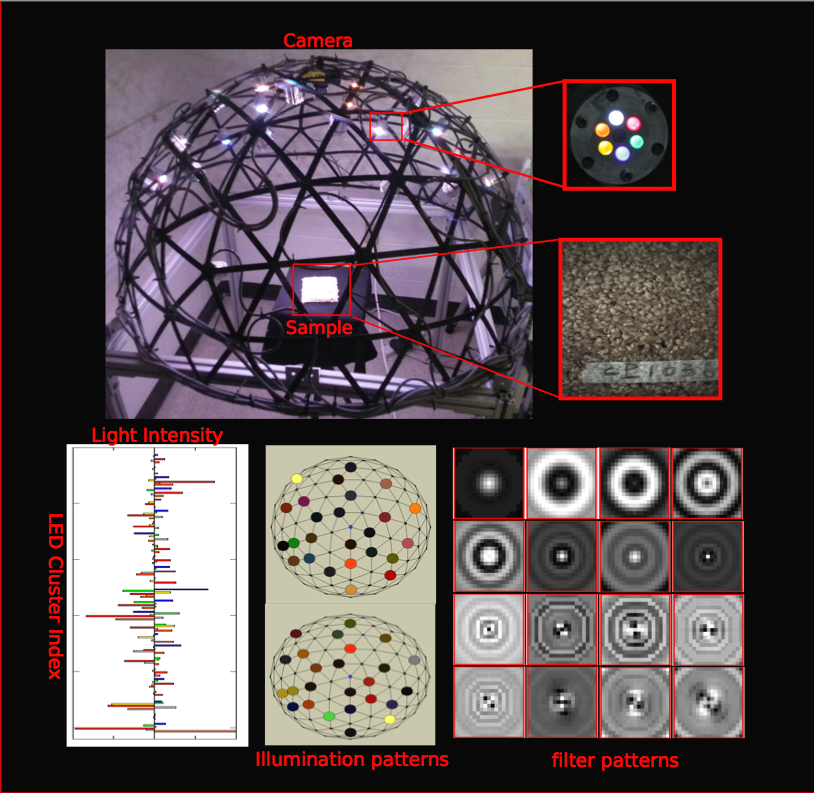

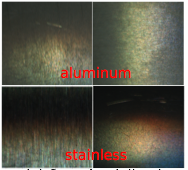

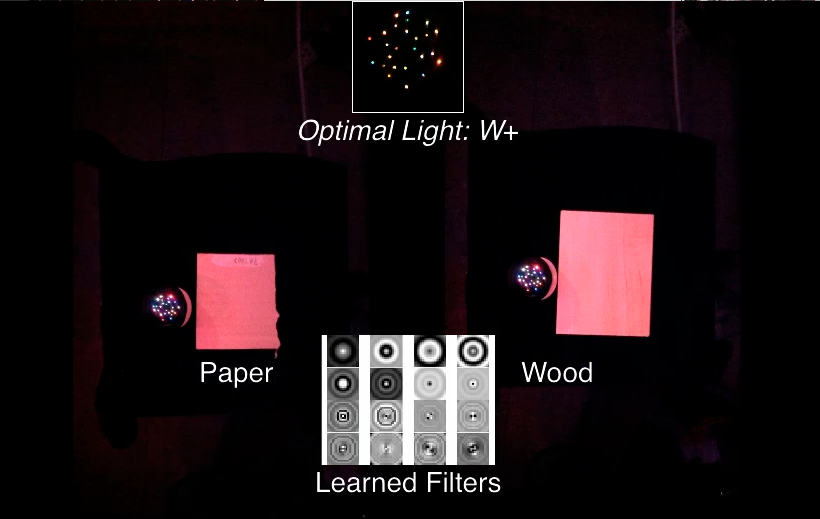

Texture classification with discriminative illumination and filters:

Texture classification with discriminative illumination and

filters. (a) Classifying aluminum and stainless steel under

conventional lighting with regular color camera is challenging,

since they have similar color and gloss. (b) We proposed to capture

projections of BTFs for material classification with coded

illumination, implemented as a LED-based multispectral dome. (c) and

(d) show the optimal illumination. The bar graph shows the learned

w, where the 25 bar groups correspond to the 25 LED clusters and the

six bars within each group correspond to the six LEDs. This coded

light pattern is also shown as w_p and w_n where w = w_p-w_n. (e)

The optimal filters. (f)(g)(h) show the classification rates on test

data using the VZ texture classifier [Varma05], BRDF Projection

[Gu09] and our method with the same number of measurements.

|

|

|

The effect of

orientation for BTF classification:

The effect of orientation for BTF classification. (a) We prepared two

materials coated with the same blue paint for material classification

with texture only. The samples measured at different orientations show

the changes in self-shadow and specular lobe caused by surface geometry.

(b) By using multiple rotated samples in training, we learned

classifiers (i.e., illumination and filters) that are more robust to

orientation. (c) As expected, the accuracy of our BTF projection method

increases with the number of rotated samples added to the training set,

while the BRDF projection method [Gu09] does not vary significantly.

|

|

|

The effect of scale for BTF classification:

(a)(b) show the images of carpet and paper captured at two different

scales. (c)(e): the optimal illumination (w_p, w_n) and filters

trained with samples in one scale. (d)(f): the optimal illumination

(w_p, w_n) and filters trained with samples in both scales. The

differences in the trained illumination and filters confirm that BTF

is not scale-invariant. (g): classification results when only

samples in one scale are included in the training set. (h)

classification results when samples in both scales are included in

training set. The classification rate increases as the training sets

include both scales.

|

|

|

Comparisons with other texture-based methods:

The classification for aluminum and stainless steel samples. (a)

Images of samples when all LEDs are turned on; (b) VZ classifier ;

(c) 3D texton; (d) BRDF projection; (e) BRDF projection coupled with

optimal filters; (f) Our method. The accuracy is shown in the

bracket.

|

|

|

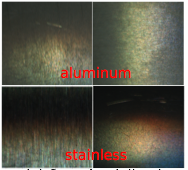

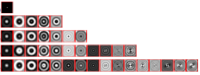

Trained filter banks with different filter sizes:

From top to bottom, the filter sizes are: 3 x 3, 7 x 7,11 x 11, 19 x

19 and 27 x 27, with the classification rate for the task aluminum

vs. stainless shown to the bottom of each filter bank. The

corresponding filters, shown in the same column, are not necessarily

the scaled versions of each other due to two reasons: 1) increasing

the filter size does not necessarily include more informations about

the texture due to the repetition of patterns. 2) As the filter size

increases, it is more likely to include outliers, such as the

specular lobes, into the training set.

|

|

|

The filters in the

optimal filter banks with different number of filters:

The filters in the optimal filter banks with different number of

filters. Shown on the left side are the number of filters in the filter

bank and the classification rate for the task aluminum vs. stainless

steel. As shown, the performance for this task increases fast with the

number of filters. This indicate that the classification of aluminum

and stainless can be performed well on a subspace of BTF with lower

dimensionality. The observation is similar in [Varma05] that some

texture classification tasks can be performed well even though the

sampling patch size is small (i.e., using more local feature).

Within each filter bank, the spatial frequency of the learned filter

increases with the index of filter. This indicates that the

difference of the projection of BTF is concentrated on the low

spatial frequencies.

|

|

Video

If you are having trouble viewing these .mp4 videos in your browser, please save them to your computer first (by right-clicking and choosing "Save Target As..."), and then open them.

|

|

Supplementary Video:

This video includes more experimental results. (2.3MB)

|

|

Slides

CVPR 2013 Poster

|

Discriminative Illumination for BRDF Classification

Material Classification with BRDF Slices

Optimal Illumination for Material Classification

|

|